Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Ms. Gracie Ge

What can I do for you?

Recently, with the market development and application of automotive electronics and power electronics, it led to electronic devices with high operating current, high temperatures and high frequencies. To meet the stability of the devices and circuit work, higher requirements are placed on the chip carrier. Therefore, ceramic substrates with high thermal conductivity and low expansion have started to become the basic material for high-power electronics circuit structure technology and interconnection technology.

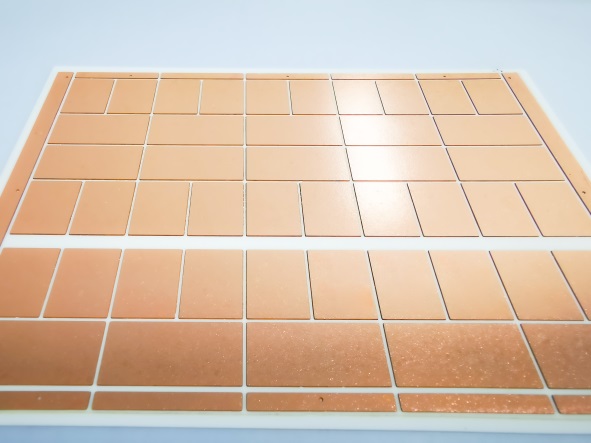

There are five common types for ceramic substrates at current stage: HTCC.LTCC.DBC.DPC.LAM. Among them, DBC and DPC are only developed and matured in recent years in China, and can be mass produced as a professional technology. SHAOXING HUALI ELECTRONIC CO., LTD. mainly produces ceramic substrate belongs to DBC Substrate.

DBC (Direct Bonded Copper) Substrate is a special process board where copper foil is bonded directly to the surface (single or double sided) of and AI203 OR AIN ceramic substrate at high temperatures and can be etched with various graphics. It has excellent electrical insulation performance, high thermal conductivity, excellent soft brazability, high adhesion strength and a large current-carrying capacity. DBC Substrate mainly used in the fields of rail transit, smart grid, new energy vehicles, industrial frequency conversion, household appliances, military power electronics, wind and photovoltaic power generation. Its superiority is as follow:

1. A ceramic substrate with a coefficient of thermal expansion close to that of a silicon chip, which saves the transition layer of Mo chips, saving labor, material and cost.

2. Excellent thermal conductivity, making the chip package very compact, thus greatly increasing the power density and improving the reliability of systems and devices.

3. A large number of high-voltage, high-power devices have high requirements for heat dissipation, and ceramic substrates have a better heat dissipation effect.

4. Ultra-thin (0.25 mm) ceramic substrates can replace BeO, without environmental toxicity problems.

5. Large current carrying capacity, 100 A continuous current through 1 mm wide 0.3 mm thick copper body, temperature rise of about 17 ℃; 100 A continuous current through 2 mm wide 0.3 mm thick copper body, temperature rise of only about 5 ℃.

6. High insulation withstand voltage, to ensure personal safety and equipment protection

7. New packaging and assembly methods can be realized, resulting in highly integrated products and reduced size

8. The ceramic substrate is highly resistant to vibration and wear, ensuring its long service life.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.