Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Ms. Gracie Ge

What can I do for you?

![]() August 29, 2022

August 29, 2022

As we move further into the 21st century, technology continues to explode. Several industries, in particular, are expected to see significant advances in the coming years, thanks to new and emerging technologies such as green hydrogen fuel cell technology, automation, and telemedicine.

The energy, e-mobility, industrial manufacturing, and medical device industries are using these new technologies to satisfy growing environmental concerns as well as consumer trends. All of these industries are expected to experience continued growth and so will the quest to find quality, cost-effective components to power their systems.

With such a wide range of potential uses, it’s no wonder chemical metal etching is becoming more and more popular among manufacturers. This blog post will explore some industrial applications derived from this new technology that benefit from chemical etching.

Photo chemical etching (PCE) is a metal fabrication process using digital tooling, photoresist film, UV light, and acid to dissolve portions of unwanted metal on parts. It has been used in circuit boards and other precision metal parts for many years, including EMI shielding, lead frames, screens, and electrical contacts and terminals. This technology has been renewed interest due to its potential to manufacture emerging technologies using fuel cell plates, encoder disks, and other micro components for smaller connected devices.

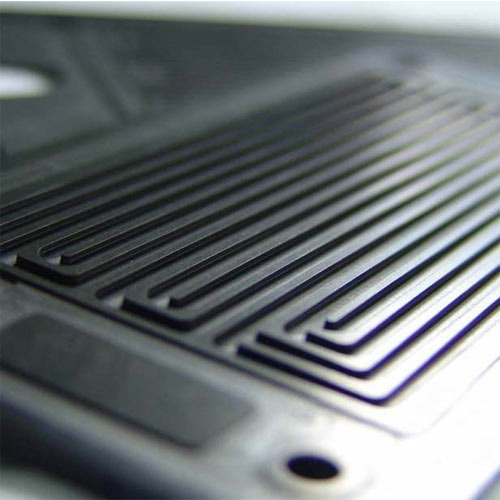

Chemical metal etching is a perfect solution for fabricating fuel cell plates, bi-polar plates, and heat exchanger plates, all of which have the same features.

The etching process is proficient in creating various directional flow channel patterns in the metal, making it possible to produce complex shapes that are difficult or impossible to achieve with other fabrication methods.

For example, laser cutting can cause micro burrs or thermal distortion, and stamping increases the likelihood of stress from the hard physical tooling. There is no physical stress with metal etching, and the metal properties remain unchanged.

Etching can have reduced lead times than laser cutting because all the features and openings are etched simultaneously. And compared to stamping, the etching prototyping process is quick, and modifications to the tooling are inexpensive.

E-mobility is a growing industry, and electric vehicles are increasing in popularity. The current administration introduced a 50 percent electric vehicle (EV) target for 2030, It’s clear that this is a ripe market for growth!

One of the biggest challenges facing the electric vehicle industry is a reliable and efficient way to store energy. Batteries are currently the most popular way to store energy in electric vehicles, but they have several drawbacks. They are expensive, bulky, and heavy, making them difficult to transport and limiting their range. In addition, batteries are slow to charge and have a limited lifespan.

Fuel cells powered by hydrogen offer a promising alternative to batteries for electric vehicles. Fuel cells are much lighter and more compact than batteries and can be charged quickly. They can also power a vehicle much longer than just a batter alone.

The challenge for the electric vehicle industry is to find a way to make fuel cells plates that are affordable and easy to manufacture. Stamping tooling is expensive and can be costly for prototyping. Chemical machining is a more cost-effective option, from prototyping to medium-sized volumes.

Since car manufacturers are looking to reduce weight, aluminum would be a good option for fuel cell plates. Although aluminum is not easy to manufacture with some processes, it is not an issue for photo chemical etching.

From AME (ADVANCED METAL ETCHING)

The above is the Chemical Metal Etching and Today’s Innovative Technology - Fuel Cell Plates we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.